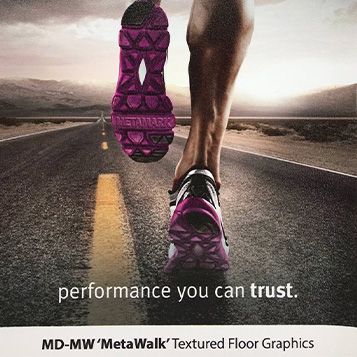

MD-MW METAWALK (R10) 1370x30MT

Product Information

MetaWalk MD-MW-R10 is a one-part printable floor media system for use in dry conditions. The textured product is designed for temporary floor graphics, applied to smooth indoor floor surfaces in good condition, or indoor short pile carpets. MD-MW-R10 can with stand regular levels of foot traffic. It has an anti-slip finish tested to DIN 51130:2014, achieving an R10 rating allowing use in dry areas and when wearing footwear or to smooth, sealed surfaces, or for use on short pile carpets.

The product gives a highly vibrant print image, retaining greater intensity of the colours, and has a high level of opacity.

Features:

- 150 Micron

- Polymeric Calendered PVC film

- MetaScape air release permanent solvent based adhesive.

- Texture finish for one Part Floor Media System, no need for lamination

- Slip Rating BS 7976-2:2002 Certified Slider 96 DIN 51130:2004 R10

- External weathering Indoor 3 – 6 months. This refers to the unprinted vinyl

- Suitable for use on Solvent, Eco Solvent, Latex and UV printers

- REACH Compliant

Please note: Slip resistance may alter with printing process.

More information in the FAQ tab below.

We deliver all over Australia!

Check our FAQ's for lead times.

Talk to an expert. We're on hand to help with any of your questions 8am-5pm,

Monday to Friday.

![]() Call our team on 1300 713 567.

Call our team on 1300 713 567.

Face Film:

- 150 micron

- Polymeric Calendered PVC

Adhesive:

- MetaScape air release permanent solvent based adhesive

Release Liner:

- Print ‘MetaScape’ print

- Weight 140 gsm nominal

- Type Structured PE layflat

Finishes:

- MD-MW-R10 White

Durability:

- External weathering Indoor 3 – 6 months. This refers to the unprinted vinyl

- Fire Rating Class C. BS EN 13823 C-S1-D0

- Slip Rating BS 7976-2:2002 Certified Slider 96 DIN 51130:2004 R10

- REACH Compliant

Printing and Handling:

- Always perform a test print first.

- Ensure that the correct profiles and heater settings are used. Refer to www.metamark.co.uk.

- Ensure that the material has reached room temperature and a relative humidity of 50% before printing.

- For use without lamination.

Application:

- Allow a minimum of 24-48 hours for the solvents to dry off before application of the overlaminate, or to the vehicle, depending on the print and drying conditions this can often be in excess of 48 hours. Retained solvents will reduce adhesion levels.

- Ensure the floor surface is clean from contamination, dust free, and dry before applying graphics.

- Apply using a dry application method, to smooth, flat, sealed surfaces only.

- Testing for suitability is recommended prior to applications.

- Make sure edges are applied well. Allow 24 hours to cure before being exposure to moisture or cleaning.

- Avoid exposure to heavy traffic. If edges of graphics begin lifting, replace graphics immediately to avoid the risk of tripping hazard.

Notes:

- Slip resistance may alter with printing process.